Polyurethane engine and gearbox bushings

Polyurethane bushings are an alternative to conventional rubber bushings. They are used mainly in chassis parts (arms, axles or mounts) but it is not uncommon to use them for propulsion systems (engine and transmission) as well. In this article, we'll discuss when is the right time to consider their replacement, their pros and cons, and why is polyurethane better choice over standard rubber, or the oppostite.

Most of the engine and transmission bushings in production cars are made of rubber. After the (petrol) engine has warmed up, they produce almost no vibrations in the cabin. The hardness of the rubber of the factory engine bushings is therefore chosen so that comfort is more important than restriction of the movement of mechanism (with exception in purely sports cars). In this article, we will share the experience with our cars.

BMW E36 328i

BMW with the R6 engine uses two main engine bushings and two transmission bushings for mounting. The fact that stock engine bushings are pretty soft and that these cars are not new both play part in situations when after a few trackdays, slaloms or drifts, you could be left with the engine just hanging on the axle, due to a torn silentblock (speaking from my own experience :D).

SHIFTING VS BUSHINGS

Another problem arose when we switched to a short-shifter with a fixed backdrop in the BMW, where the shifter was connected to the body and the rod connected directly to the gearbox. This meant that all the movement of the gearbox and engine was transmitted to the gear lever. As you can see in the attached video below, the extreme vibration during hard acceleration or hard braking had the engine and transmission moving right across the engine bay. Sometimes it happened that the gears would jump or wouldn't even go into gear. At first we thought there was a problem with the rod, but after a while it was clear that the problem was somewhere else, in the engine's bushings. In the following video you can see how the lever moves in a wet race on the semi slick tires :D the movement of the lever directly illustrates the movement of the engine

HOW TO SOLVE THE PROBLEM?

After talking to a friend from abroad, we were advised to use a polyurethane solution.

DEUTER Motorsport produces polyurethane with two hardness grades, 75SHA and 85SHA.

We opted for the harder option (we didn't want to hold back :D) as the car is mainly

used for autoslalom driving. Already the first kilometers after installation showed a big change,

the gear shifting was significantly more precise both during acceleration and braking.

Overall, the car seemed to stiffen up, and suddenly no propulsion system movement could be felt.

This made all the shifting problems disappear completely (see attached video). Admittedly, there is

still minor "dancing" of the shifter to be seen, but it's considerably better than before.

We could also feel a very pleasant change of comfort. Since the inline-six engine in the BMW is an incredibly balanced engine in terms of running, there were no hellish vibrations in the bodywork, quite the opposite. The engine in our E36's idle speed has been raised slightly from 650 rpm to around 950 rpm (due to a lighter flywheel and sharper cams), and this too has obviously contributed to no loss of comfort, or understeer of the car at idle. Overall, engine and gearbox movement in the engine bay was limited to almost nil.

FOR THOSE LESS WILLING TO COMPROMISE

For fans of less compromising solutions, we recommend using

the STRONGFLEX BMW E36 engine bushings

,

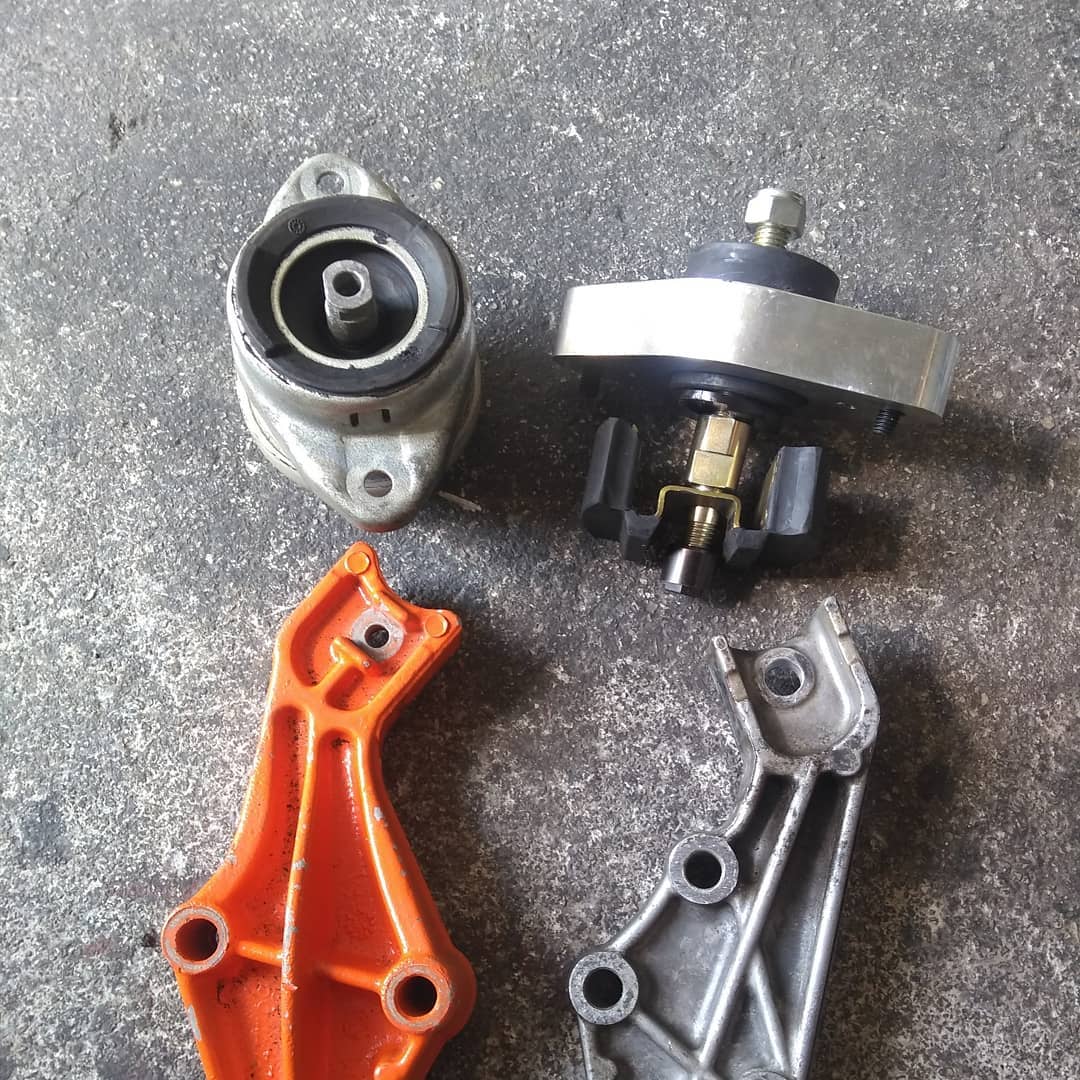

which are composed of aluminium and polyurethane.

Strongflex

bushings are even slightly harder than the Deuter Motorsport engine bushings.

For the utterly uncompromising, there's still the option of fitting the engine

and gearbox to pure aluminium bushings. This solution is only recommended for

pure race cars where a zero propulsion system movement is required.

OUR RECOMMENDATION

So let's take a look at the DEUTER motorsport engine and gearbox bushings for the BMW E36:

- Significantly restricts engine and gearbox movement (suitable for application of a shortshifter with a fixed backdrop)

- A minimal loss of comfort

- A more robust and stiffer driving feel

- More precise shifting even under hard braking or acceleration

- Excellent price/performance ratio

So if you're willing to sacrifice a minimum of comfort and are looking for a necessary improvement in driving enjoyment, this is the right choice. I've had them in my car for the second year now and I can't get enough of them, and neither can our customers, e.g. on the BMW E46 M3 or the BMW E30 M50 Turbo.

Citroen Saxo VTS 1.6 16V R4

In the case of our second car, the Citroen Saxo VTS, the problem of engine and gearbox movement is a little more complex. As the engine is mounted transversely, the car essentially has three propulsion system bushings (the engine one, gearbox one and the lower swinging bushing).

HOW NOT TO "MESS IT UP" IN PRODUCTION

The stock Saxo (even the VTS version) was made predominantly as a city car, so the original bushings are not ideal for sport driving. Not only are they too soft and the engine flies around, but the engine mount itself is "French undersized". The main engine bushing is held in place by an M8 bolt, which is not a big problem to rip off while driving harshly.

FROM SHOPPING CART TO ATHLETE

Since a straight-four engine is not as balanced in terms of running as the inline-six engine, we recommend using main engine and transmission bushings made of hardened rubber for sport driving.

Our car uses sharper CATCAMS compared to the stock engine, so the idle is quite

unsteady (video). Despite this, we decided to use BAKER BM bushings in rally

Group N specification as using stock bushings for sport driving is totally inappropriate.

These significantly reduced the engine movement. In cold weather, the engine is indeed

damped and transmits minor vibrations to the dashboard, but when the engine warms up,

the vibrations get to an acceptable level and I don't think any sports driving enthusiast

would mind. With our engine having the aforementioned sharper cams, I believe the vibration

with a stock engine would be even less apparent. One of the big advantages, besides the

reduction in movement, is that the bushings use M12 bolts for mounting (I wonder why...).

Thus, after enlarging the hole in the motor mount to the appropriate diameter, the

problem of the bolt breaking completely disappeared.

TOILET BELL OR GEAR LEVER?

It's not said for nothing that the stock gearshift in a Citroen is very similar to a toilet bell. Firstly because of the large number of joints between the gear lever and the gearbox, which are just a place for more clearance, but of course also because of the stock engine bushings, the running of which will show up in the clearance in the gear lever. As with the BMW, the harder bushings have helped to make the shifting more precise, but it doesn't solve the whole shifting problem with this "Frenchman". After the harder engine bushings, we also recommend replacing the rods with aluminum/uniball ones, and replacing the shift bracket with a uniball one as well. This will make shifting in this car significantly more enjoyable.

DISADVANTAGES?

As already written, in most hatchbacks a straight-four engine is used, the operation of which is not perfectly "smooth", the application of harder bushings can cause the transmission of vibrations to the body, especially in cold weather. This brings us to the second problem, which is the bolt stripping on the car due to the slight vibrations transmitted to the bodywork. If you don't want to tighten half the car after every race or drive on the edge, we recommend using thread adhesive on all the joints around the engine bay.